ABOUT US

METALPOL is a family-owned company with over 50 years of experience, located in the Special Economic Zone in Mielec, southeastern Poland. We specialize in the production of springs and custom wire-formed components, manufactured to order based on drawings, samples, or 3D models

Our offer includes:

- compression, extension, torsion and spiral springs

- formed 2D/3D parts

- stamped parts from steel tapes

- corrosion-resistant coatings using our automatic zinc flake coating line

- comprehensive spring design services using professional CAD/CAM software

We serve a wide range of industries, including:

- aerospace

- automotive

- industrial engineering

- agriculture

- railway

- electrical and electronic engineering

- medical technology

We operate a modern, automated machine park, a specialized measurement laboratory, and a highly experienced technical team. The quality of our products is confirmed by ISO 9001 and IATF 16949 certifications, making us a trusted partner for even the most demanding customers.

COMPANY HISTORY

Beginnings (1968–1990)

Metalpol was founded in 1968 in Mielec as a family-owned business focused on the production of metal components. In its early years, the company operated on a craft scale, producing simple wire and strip products for local customers.

Technological Development (1990–2000)

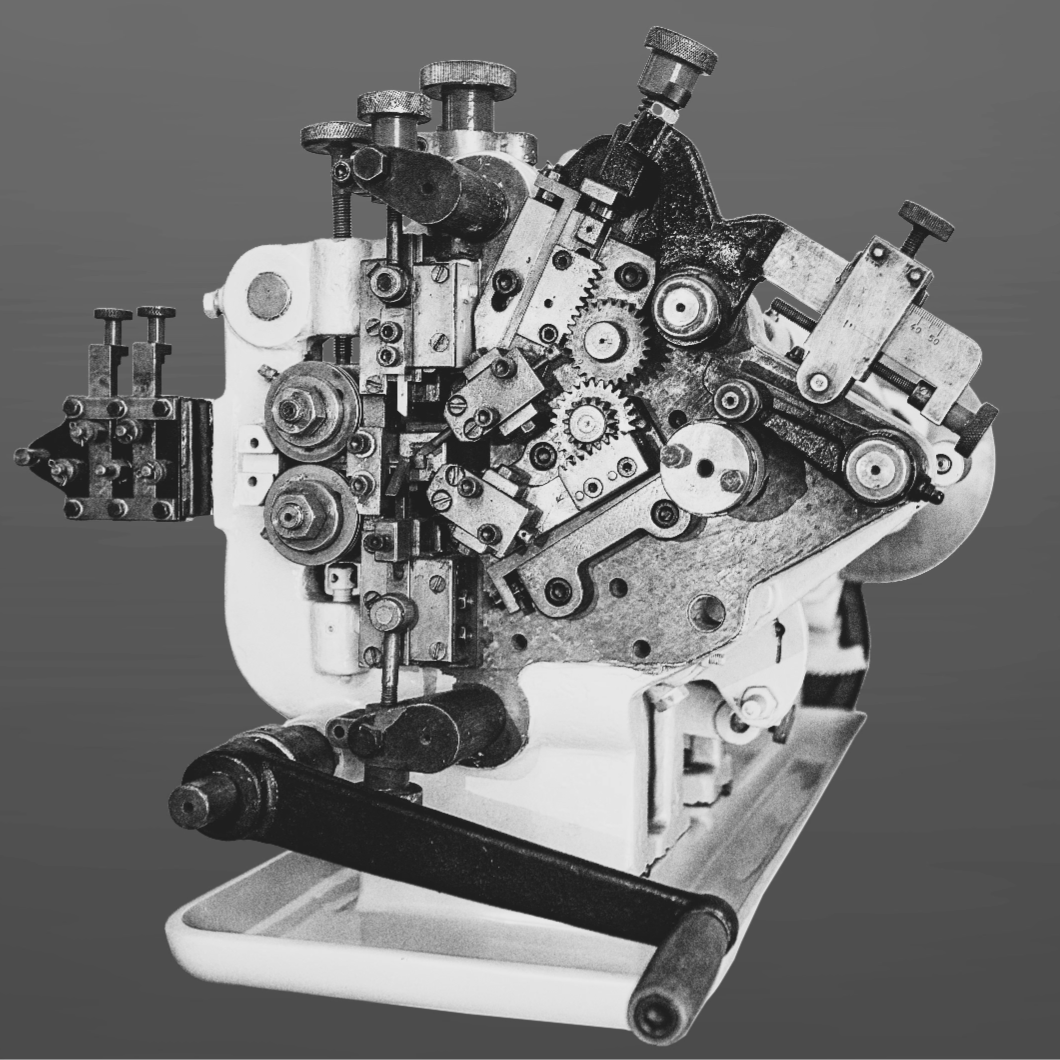

In the 1990s, responding to economic transformation and increasing market demand, Metalpol began modernizing its machinery and expanding its product portfolio. The company started manufacturing compression, extension, and torsion springs, as well as more advanced bent wire and strip components.

Market Expansion and Certification (2000–2010)

During the first decade of the 21st century, Metalpol invested in production automation, implemented CAD/CAM design systems, and established a quality control laboratory. The company obtained ISO 9001 certification and received authorization from the Polish Ministry of the Interior and Administration to manufacture components for military applications. These developments enabled cooperation with larger industrial clients.

Specialized Production and Growth (2010–2020)

Metalpol began supplying customers in industries with stringent quality requirements, including automotive, aerospace, rail transport, and medical sectors. The company also obtained the IATF 16949 certification, essential for automotive suppliers. Production capacity was increased, and a proprietary lamellar zinc coating line was introduced to provide effective corrosion protection.

Today and Beyond

Today, Metalpol operates in a modern production facility located in the Special Economic Zone in Mielec, at 13 Kwiatkowskiego Avenue. The company employs several dozen specialists and serves over 500 clients in Poland and abroad.

Metalpol handles orders ranging from individual prototypes to large-scale production, based on technical drawings, 3D models, or physical samples provided by customers. With over 50 years of experience, technical flexibility, and a strong focus on quality, Metalpol remains a trusted partner for companies seeking precision springs and components made from wire and strip materials.

Sustainability

At METALPOL, we believe that responsible manufacturing is key to long-term success — for our company, our customers, and the environment. As a manufacturer of precision springs and wire components, we are committed to integrating sustainable practices at every stage of our operations.

What Sustainability Means to Us:

- Efficient Resource Use

We continuously optimize our production processes to reduce material waste and energy consumption. Our machines are selected and maintained for high efficiency and minimal environmental impact. - Responsible Material Sourcing

We work with certified suppliers and prioritize materials that meet European environmental and safety standards, such as REACH and RoHS compliance. - Waste Management and Recycling

Scrap materials from spring production are sorted and recycled whenever possible. We also implement waste-reduction strategies in packaging and logistics. - Long-Life Products

By delivering durable, high-quality springs, we help our customers reduce the need for frequent replacements, supporting longer product life cycles and reducing industrial waste. - Continuous Improvement

We actively monitor our environmental footprint and invest in new technologies that help us reduce emissions, energy usage, and material consumption.

At METALPOL, sustainability is not a trend — it’s a responsibility. We’re building a company that supports both innovation and the environment for generations to come.